BMW Electric Motors and Transmissions Production

BMW has created more space for the production of electric drive components at the Dingolfing location. Production and storage halls, which still date from the time of Hans Glas GmbH, were demolished, and the two-story building number 33 was created with a net usable area of 10,000 square meters. According to the company, a “medium double-digit million amount” was invested.

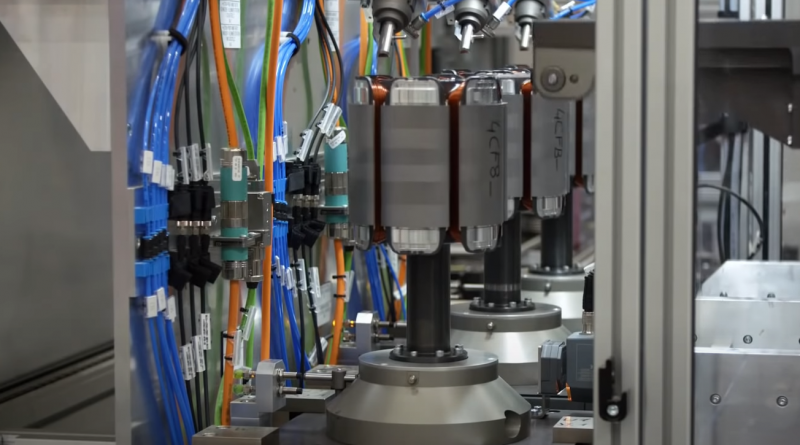

In addition to the wheel sets for the BMW i3 and E-Mini electric transmissions, the new building will also produce other components for the fifth-generation electric drives, which will be installed in the new electrified models in the future – in the iX3 (production in China ), i4 (Munich) and iNext (Dingolfing from 2021). E-components have been manufactured at the Lower Bavarian location since 2013. In the meantime, Dingolfing has also become a “competence center for electric drive production”. A total of around 2500 employees currently work in this part of the Dingolfinger BMW plant (2.10), who in addition to axles, wheelsets and axle drives, also manufacture chassis parts and the electrification components for the i models.

According to the company, the new building was built in around 14 months and will have the first green roof in the Dingolfing works network. The sowing was just taking place.

BMW Group plant in Dingolfing

The BMW Group Dingolfing plant is a network of BMW plants at the Dingolfing site with a total area of around 280 hectares.The BMW Group Dingolfing plant is the largest production base of the BMW Group in Europe.

History

The origins of the BMW Group plant in Dingolfing go back to the former Hans Glas GmbH, which had been based in Dingolfing since 1905. After the takeover of Hans Glas GmbH by BMW AG in 1967, the Goggomobil was still produced until 1969. On November 9, 1970, the foundation stone was laid for today’s vehicle factory at 02.40; the first BMW 5 Series rolled off the assembly line there on September 27, 1973. Since then, the Dingolfing plant has produced more than eleven million BMW vehicles.

Interesting Facts

The Dingolfing plant is one of the BMW Group’s 31 production sites worldwide and the company’s largest European manufacturing facility. Around 1,500 automobiles of the BMW 3, 4, 5, 6, 7 and 8 series roll off the assembly line here every day in the automobile plant. In total, the plant manufactured around 285,000 vehicles in 2019.

In addition to automobiles, vehicle components such as pressed parts or chassis and drive systems are also manufactured in Dingolfing. The Group-wide competence center for electric drive production is located in component plant. From here, BMW Group’s vehicle factories worldwide are supplied with electric motors and high-voltage batteries for the production of plug-in hybrids and pure electric models. This electric drive production is currently being expanded significantly and is expected to grow to up to 2,000 employees in the medium term.

In addition, the body shells for all Rolls-Royce models are built at the site. The so-called dynamic center, a large storage and handling center and the heart of the BMW Group’s central aftersales logistics, supplies the worldwide BMW and MINI dealer organization with original BMW parts and accessories.

Plug-in hybrid variants of the BMW 5 and 7 series are already being produced on a assembly line in a mix with diesel and petrol models. The BMW iNEXT will be the first fully electric model from Dingolfing’s production to start up in 2021.

Around 18,000 people are currently employed at the location in Lower Bavaria. With an additional 800 trainees in 15 apprenticeships, Dingolfing is also the largest training company in the BMW Group.

A special feature of this plant is commuter bus transport , which brings employees from large parts of Lower Bavaria, parts of the Upper Palatinate and Upper Bavaria to Dingolfing. This was introduced to reduce the traffic load in the small town of Dingolfing with its 18,000 inhabitants. Up to 300 buses serve 2,500 stops a day and bring 13,000 employees to Dingolfing. They cover 43,000 kilometers a day. The most distant bus stop is in Jandelsbrunn. For the 128 kilometers, the bus takes about an hour and forty minutes.